Explanation of working principle of refrigeration equipment of refrigeration unit

1、 Screw compressor composition

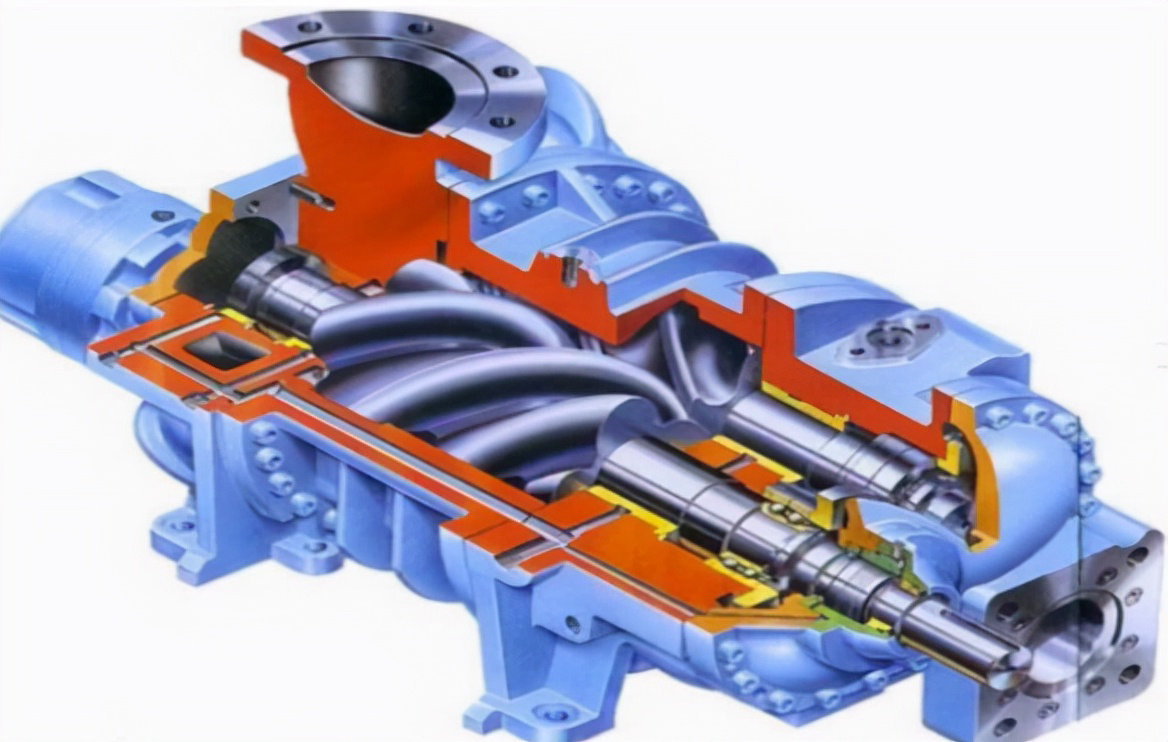

Generally speaking, the refrigeration unit generally refers to the refrigeration compressor, which is an energy adjustable compressor. In its category, the screw compressor is mainly composed of a pair of parallel and meshing female and male rotors, bearings, balance pistons, shaft seals, gas transmission regulating devices and other components.

2、 Refrigeration compressor category

According to its principle, refrigeration compressor can be divided into volumetric compressor and speed compressor. Volume type is divided into: reciprocating compressor and rotary compressor. Speed compressors are divided into axial compressor, centrifugal compressor and mixed flow compressor.

As the name suggests, the purpose of refrigeration compressor is refrigeration. For example, the compressor used in refrigerators and air conditioners commonly used in our family belongs to positive displacement type, and the positive displacement compressor can be subdivided into reciprocating and rotary type. Reciprocating compressor is a kind of compressor that changes the volume of cylinder periodically through the reciprocating motion of piston or diaphragm in cylinder and realizes the pressurization and transmission of gas.

Rotary compressor means that the motor does not need to convert the rotary motion of the rotor into the reciprocating motion of the piston, but directly drives the rotary piston to do the rotary motion to complete the compression of refrigerant vapor.

In the field of commercial and industrial refrigeration, compressors are mainly divided into centrifugal, scroll and screw compressors. Among these three types of compressors, screw compressors are widely used. The following industrial cooling collection takes screw compressors as an example to explain their working principle and application fields.

3、 Working principle of screw compressor

The screw compressor relies on the meshing male and female rotors to complete the process of lifting low-pressure gas into high-pressure gas with the help of a pair of "V" shaped inter tooth volumes formed by their teeth, tooth slots and the inner wall of the casing. The specific working principle is that the rotor groove is filled with gas when it passes through the suction port. When the rotor rotates, the rotor groove is closed by the casing wall to form a compression chamber, When the rotor groove is closed, the lubricating oil is sprayed into the compression chamber for sealing, cooling and lubrication. When the rotor rotates to compress the lubricant and refrigerant, the evaporator obtains gaseous coolant, which enters the condenser and is liquefied to take away heat, so as to realize the refrigeration cycle of compression → condensation (exothermic) → expansion → evaporation (endothermic).

4、 Advantages of screw compressor

According to the principle of compressed gas, the screw compressor is the same as the reciprocating compressor, which is a positive displacement compressor. In terms of its motion, the rotor of the screw compressor and the rotor of the centrifugal compressor belong to high-speed rotary motion, so the screw compressor has the following advantages:

1. High speed, light weight, small volume and small land occupation.

2. Good power balance performance.

3. Simple and compact structure, few vulnerable parts, simple maintenance and reliable use.

4. Insensitive to liquid hammer and high single-stage pressure ratio.

5. The gas transmission is hardly affected by the exhaust pressure, and can still maintain high efficiency in a wide range of working conditions.

However, for screw compressors, they are not without disadvantages, but the disadvantages such as noise, huge auxiliary equipment and processing rotors are smaller than those of other refrigeration compressors, and even York screw compressors in the industry can overcome the above disadvantages.

5、 Application field of screw compressor

Screw compressors are widely used in iron and steel metallurgy, petrochemical industry, paper printing and dyeing, pharmaceutical and food, thermoelectric power and other industries, especially York screw compressors in lubricating oil degreasing and deoiling, paraffin molding, liquefied petroleum gas, liquefied natural gas storage and transportation, natural gas dew point control, natural gas compression, gas compression, high and low density polyethylene, polypropylene, CIS polybutadiene rubber The refrigeration effect of synthetic ammonia, acrylonitrile, acetate fiber and other fields is remarkable, which is recognized by customers.

LATEST NEWS

- What is the difference between refrigerator refrigeration single cycle, double cycle and three cycle? How to distinguish? 2021-12-06 15:33:40

- What is a two-stage compression refrigeration cycle? 2021-12-06 15:32:32

- Why did semiconductor refrigeration not replace compressor refrigeration? 2021-12-02 13:57:29

- Explanation of working principle of refrigeration equipment of refrigeration unit 2021-12-02 13:50:37

- Details needing attention in improving reaction rate of industrial high and low temperature circulating device 2021-12-02 13:48:26

- What is the role of China's breakthrough in ultra-low temperature refrigeration technology, which is 0.01 degrees different from absolute zero? 2021-12-02 13:43:08

Nicole Wu

Email: sale5@pro -valves.com

MOBILE: +86 13968609917